Cartridge Filter

Cartridge filter is made up of two parts:

- Cartridge-which is filtering device

- housing-The cartridge is to be housed in line by proper housing.

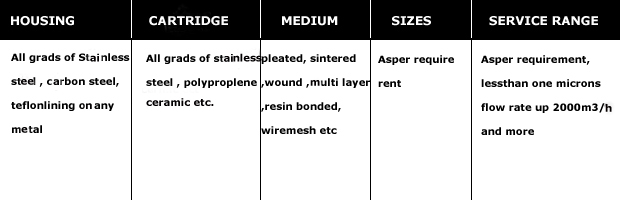

Cartridge filter normally used as polishing filter in almost all process industry.Cartridge filter is constructed of filter housing,filter cartridge,tube sheet,positive sealing arrangements for cartridge depending upon type of cartridge & choice of end connections.The number of cartridge are selected on the basic of micron size and flow rate of permissible pressure drop.Different material available for the cartridge are polyproplene,cotton,sintered SS,ceramic etc.Housing are available all grade of stainless steel,alloy steel and teflon,lining on any metal.

Operation:

Contaminated fluid enters the housing and is distributed evenly around the filter cartridge,filtration takes place from outside to inside.Solids are collected on the outside of filter cartridge & clear filtrate is collected at outlet.

Features:

- No moving parts.

- Leak proof tongue & groove body flange joints.

- Designed for easy cartridge fixing.

- Various cartridge options.

- Complete closed systems.

- Housing as per pressur vessel design code.

Advantage:

- Fine filtration,less than ONE micron.

- Simple design for easy cartridge replacements.

- Flexible filtration rating in same equipments.

- Higher cake holding capacity.

- High flow rate up to 2000 m3/hr & more.

- Zero emission to environments.

Application :

- Pharmaceticals

- Processing Chemicals

- Petroleum Products

- Paints & Inks

- Dairy

- Food & Beverages

Availability Range :