Ribbon Blender

Opertion:

Ribbon Blender are widely used for homogeneous mixing of dry granules & powder.The blender consists of horizrontal "U"-shaped through with two sets of sprial ribbons,one inside the other.Inner and outer ribbon are perfectly arranged that during rotation,the material reaches each corner of the trough and in parts radial & linear motion to the whole of the material to be mixed.At the same time material is moved from side of the trough to the center and vise versa resulting in through mixing across the entire cross section of the blender.The clearance between ribbons outer edge and the through wall typically range from 3 to 5 mm.

Enquiry NowThe ribbon blender gives best result for mixing of dry powder & granules due to the design and shape of mixing ribbon and product container.It can be used for pharmaceutical,food,chemical and cosmetic product.

Material should be charge from the top side.There are port/ports should be provided on the top cover to charge the material as well as for air vent.One discharge valve provided at the bottom side at center of the container.The discharge height could be adjust as per the requirements,so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free.

In ribbon blender the powder moves from center to the end of container and end of container to the center of container.Hence requirements of total mixing time is very less and the RPM required are also very less.The dry material gets sufficient contineous movements due to shape & movements of ribbon & shape of the container.Which moves material for good quality of blending.

Optional Feature:

- Jacketed arrangement for heating or cooling applications can be provided.

- Spray nozzles with pressure spraying system for spraying additives in blenders during process.

- Full cover on top side of the container.

- Limit switch can be provided for safe operation so that the machine automatically stop if the cover is opened during the operation.

- Inching facility for stirrer for discharge of material.

- Process control panel with batch timer and cyclic timer for reverse and forward direction of ribbon.

- Discharge height must be adjusted.

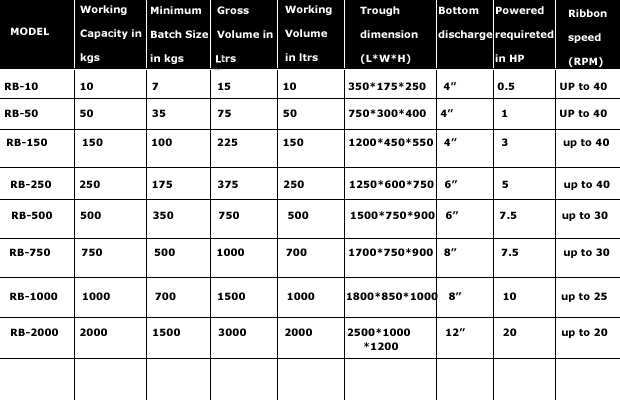

Technical Spescification